PRESTRESSED CONCRETE

INTRODUCTION

Hardened concrete as the artificial hard rock that

could be designed or made with certain desired shape from casted fresh

concrete, has some weaknesses that make it alone unfit for major structures

which are the following

- · Have

little or negligible strength against tension

- · Brittle

property (not ductile), which makes it susceptible to cracking on loading

When we design different major structures, there are

two important criteria that are put into consideration

- Safety of the structure against failure, the structure should be able to carry desired loads for intended period of time.

- Serviceability or functional of the structure, where by the structure should neither deflect in extent that it affects comfort ability of users nor lead to detaching or breaking of attached materials such as tiles of curtain walls.

Introduction of reinforcements which are ductile or

elastic material into concrete, produce reliable composite material against

cracks formation and deflection.

In order to avoid excessive deflection on major

structures such as bridges, longer spanning beams prestressed concrete were introduced in construction industry.

What is prestressed concrete?

This is a concrete in which internal stress of

suitable magnitude and distribution are introduced so that the stresses

resulting from external load are counteracted to a desired degree.

Mechanism of prestressing

In this kind of concrete, steel embedded in concrete

is stretched or tensioned to certain point not exceeding steel yield point, since

it is stretched before yield point (steel with elastic property) will try to

regain its original shape.

As high tensile steel try to regain its original

shape, it compresses concrete in which it is embedded, so concrete is

precompressed before an application of loading desired for the structure.

Ways of prestressing concrete

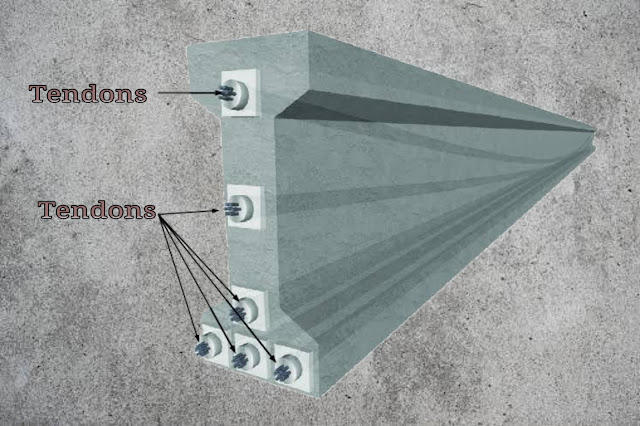

Pre tensioning,

in this method of prestressing tendons are tensioned before the concrete is

casted or poured, this methods mostly is done at factories which produce

precast units such as slabs, lintels, and beams.

High tensile strength wire strands, or bundles are set or fixed inside concrete moulds, these strands are stretched or tensioned by using hydraulic jack to a certain point not exceeding yield point of tendons.

These

steel strands after being tensioned are anchored tightly against a rigid frame at

the head and foot of the setting bed or mould, fresh concrete is poured into

the bed or mould in direct contact with the strands or tendons. As the concrete

sets, the strands become bonded to the concrete.

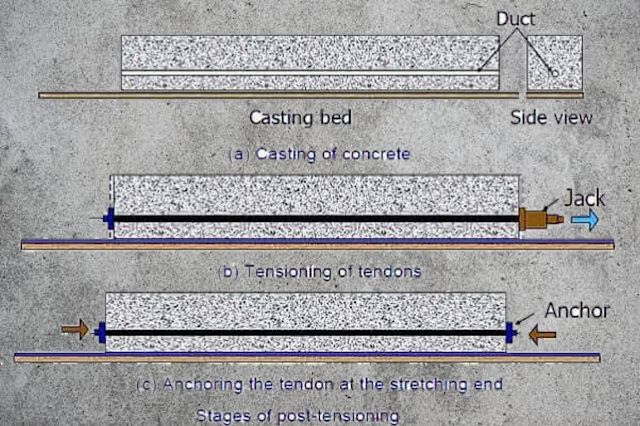

Post

tensioning, .in

this method of prestressing tendons or strands are embedded and tensioned after

concrete has casted and hardened, this process most of time is done in situ on

ready produced precast units.

The concrete is casted around ducts or

sheathing in which tendons will be housed, after concrete has been set and cured properly over time, the tendons are inserted in ducts and stretched by

hydraulic jack either on one end or both ends.

After tensioning of tendons grout is

filled into tendon ducts to assist stress distribution between concrete and

tendons, also it prevents corrosion that could be caused by entrapped moisture.

Two concept in prestressed concrete

1. Prestressing

to transform concrete into an elastic material

This is the first and most common concept among engineers;

concrete material is seen to be converted from brittle material to elastic

(ductile) material by precompression given to it from tensioned tendons.

This concrete with elastic property is not susceptible

to cracking and deflection, as it is believed that no tensile stresses are

induced into concrete.

In this point of view concrete is subjected to

external and internal forces, where by external force is resulting from tensile

force tensioning the tendons and internal force as compression force resulting

as tendons try to regain its shape.

2. Prestressing

for combination of High strength steel with concrete

Here the prestressed concrete is seen as the

combination of concrete and reinforcement, similar to reinforced concrete where

by reinforcement takes tensile stress while concrete take compression stresses,

this behavior also is exist in prestressed concrete.

In prestressed concrete, high tensile steel are

tensioned by higher tension to certain strain so steel take all tensile

stresses, as high tensile steels tend to regain their shapes compress concrete,

so concrete withstand compression stresses form steel.

Conclusion

Prestressed concrete is the strong concrete composite

that is used in major projects in construction industry such as bridges, high

raised buildings, this is due to the use

of high strength steel tendons and full

utilization of concrete compressive strength also prestressed concrete has

lower or negligible deflection when compared to reinforced concrete.

Comments

Post a Comment