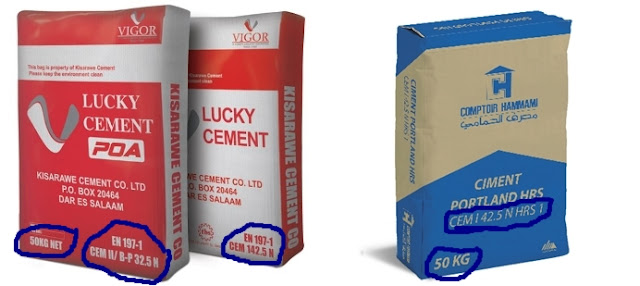

WHAT DO LABELS ON CEMENT BAGS MEAN?

DIFFERENT LABELS OF WORDS ON CEMENT BAGS HAVE DIFFERENT MEANING THAT COULD HELP YOU TO KNOW THE BETTER CEMENT FOR YOUR WORK. 1. LABELS THAT SHOW THE QUANTITY OF CEMENT The quantity of cement bags is measured in kilograms (Kgs), most of the cement bags quantity is 50 kilograms which is labels as 50 KG or 50KG NET as shown in the cement in above pictures. 2. LABELS THAT SHOW THE MATERIALS USED ON PRODUCTION The materials used for the production of cement are shown by using the abbreviation, so when it comes to the composition and ingredients in cement, there are five main types. There are denoted by a CEM value printed on the bag. The CEM value outlines the basic ratios and blends of ingredients used to make the cement. i. ...