FORMWORK FOR CONCRETE

FORMWORK

These

are temporary sometimes permanent structure

that are formed during construction process, that are used as moulds for concrete so as to attain the

concrete of desired shape and size when hardened.

In

construction industry formwork of different shapes and sizes for different

structures are constructed such as beams, columns, slabs, channels, culverts , where

by formwork of different structures are made through different ways.

In

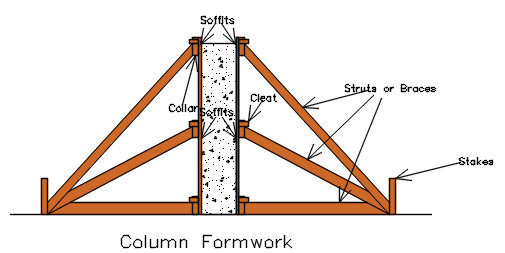

common, formwork are composed by the following components soffits, struts and stiffeners

(cleats, wales, studs, ties and collar)

Where

by each component has the same function in most of formwork for different

structures

Strut or braces these are linear member made

of timber or steel mostly inclined or horizontally provided to support and

increase the rigidity of the formwork.

Stiffeners these comprise of cleats, wales, ties and collar which hold formwork soffits at required shape and size for the concrete structure, they are also points where struts are connected to increase the strength and rigidity of the formwork.

Formwork can be classified with accordance to the materials used for making them, especially formwork surfaces.

Timber formwork

These

are formwork whereby is soffit material is the timber, these kinds of

formwork were used in old times, in these days they are not commonly as they

got some disadvantage such as they are

water absorbent which lead to distort of their shape and surface, which

make them unfit for reusing.

Mostly

of them do not produce concrete of smooth

finish as some of cement paste from concrete stick to the surfaces, so soffit surfaces need to be oiled, oil

form a layer between concrete and timber soffit which prevent sticking of

cement paste into soffit.

This kind of formwork is cheap for non repeated works and soffits can be cut into different sizes so as to fit for various structure shapes.

Plywood formwork

These

are formwork which uses plywood as the

soffit material where by components of formwork structure can be made

either by steel or timber. Plywood soffits offers water resistant surface (non absorbent) and non sticking surface (has no or little tendency to stick with

cement paste).

These

are one of mostly used kind of formwork due to its lower cost, reusing property and smooth concrete finish produced.

Also

these kinds of formwork surfaces, they

can cut into different sizes which make it applicable for construction of

structures of various shapes.

Steel formwork

These

are formwork with soffits made from steel, most of time its other structural

components are also made of steel with instructions on how to connect them to have

desired shape.

This

kind of formwork, they are prefabricated

in industries with definite shapes, they cannot be cut into different sizes

at site for different shapes other than designed one.

|

Mostly

of them do not produce concrete of smooth

finish as some of cement paste from concrete stick to the surfaces, so soffit surfaces need to be oiled, oil

form a layer between concrete and steel soffit which prevent sticking of cement

paste into soffit.

In

nowadays, there are also formwork made from other materials such as plastics, glass fibers which are also

reusable but are mostly costly.

For

a formwork to functional for a constructional work it should meet the following

the requirements.

- It should be cheap and reusable.

- Should be fitted, tightened and shaped to produce concrete structure of required shape and size.

- Should be strong to withstand pressures from concrete, vibrator, equipments and working persons on it.

- Soffits should provide smooth and non absorbent surface to concrete.

- Should be made of light materials

- Should be tightened so as to prevent any escape of cement paste.

Comments

Post a Comment